product

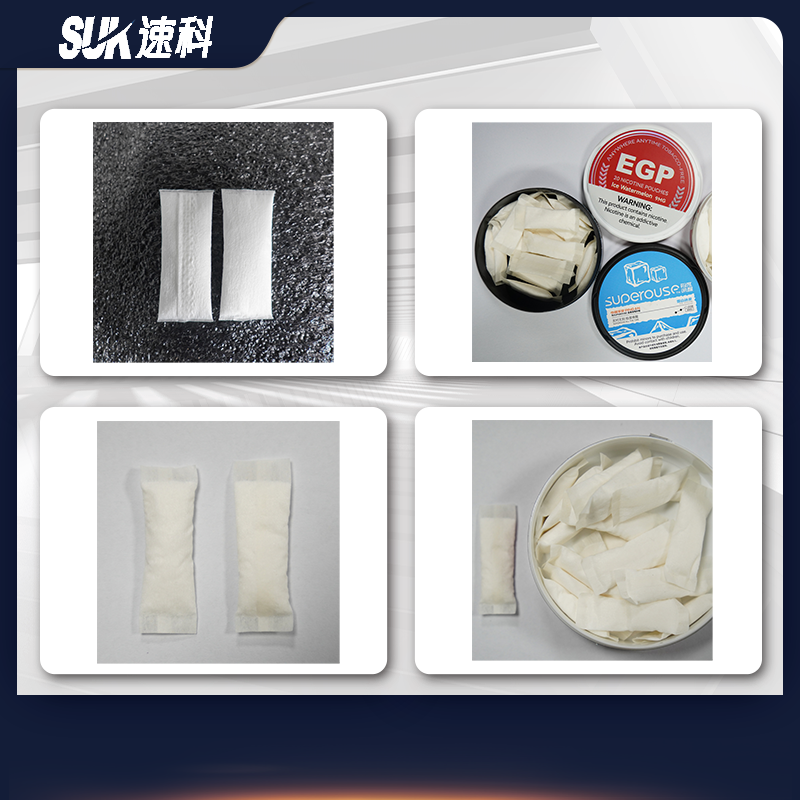

The Snuff Packaging Machine provides an efficient solution for the packaging of various snuff tobacco products. With its specialized design and advanced filling technology, it ensures product consistency and quality while maximizing production speed. This machine is essential for manufacturers looking to enhance their packaging processes and meet the demands of the snuff market.

The Snuff Packaging Machine is a specialized system designed for the efficient and precise packaging of snuff tobacco products. This machine is tailored to handle various forms of snuff, including powder and paste, ensuring that the packaging process maintains product integrity and quality. With advanced technology, this machine is ideal for manufacturers seeking to optimize their production capabilities while complying with industry standards.

| Model | SK-300BF | SK-600BF | SK-900BF |

| Packing speed | 20-40 cuts per minute/per column | 20-40 cuts per minute/per column | 20-40 cuts per minute/per column |

| Columns | 2-4 Columns | 3-10 Columns | 4-16 Columns |

| Bag Size | L:50-180mm W:20-70mm | L:50-180mm W:20-95mm | L:50-180mm W:20-105mm |

| Film Width Film Thickness | Max:300mm; 0.07-0.1mm | Max:600mm; 0.07-0.1mm | Max:900mm; 0.07-0.1mm |

| Bag Seal type | Back Seal, Three Side Seal, Four Side Seal | Back Seal, Three Side Seal, Four Side Seal | Back Seal, Three Side Seal, Four Side Seal |

| Cut type | 1.Flat cut 2.Serrated cut 3.Round corner cut 4.Shaped cut | 1.Flat cut 2.Serrated cut 3.Round corner cut 4.Shaped cut | 1.Flat cut 2.Serrated cut 3.Round corner cut 4.Shaped cut |

| Power | 3.5KW | 5.5KW | 7.5KW |

| Power supply | AC220V 1phase 50Hz/ AC380V 3phases 50Hz | AC220V 1phase 50Hz/ AC380V 3phases 50Hz | AC220V 1phase 50Hz/ AC380V 3phases 50Hz |

| Air consumption | 0.8m³/min 0.8Mpa | 0.8m³/min 0.8Mpa | 0.8m³/min 0.8Mpa |

| Dimension | 1385*918*2005 mm | 1685*1300*2005mm | 1700*1600*2500mm |

| Weights | 400kg | 600kg | 950kg |